Five indicators of a good safety floor

A safety floor is a vital part of commercial interior design – education and workplaces will often need it in canteens, corridors or entrances; healthcare spaces will want to ensure corridors and public areas have low slip risk potential, as well as hygienic surfaces. It’s also worth considering hospitality and leisure – a slip or fall could be disastrous for these experience-based businesses.

Adding attractive safety flooring into these spaces hasn’t always been easy. Safety sheet is popular and functional, useful for back-of-house spaces, store rooms and clinical environments, but it doesn’t deliver much in terms of aesthetics, or won’t be easily repaired without patches or expensive full removal and replacement.

When the majority of accidents happen at work, it's easy to see why specifying the right level of slip resistance should fit the function of a space.

1. Slip Resistance Tests

Look out for two very significant indicators – the pendulum and ramp tests. In the UK the pendulum slip test is the HSE’s preferred measure of slip resistance. A score over 36 in the WET test indicates a significant level of slip resistance. It’s a test that mimics the friction a person’s shoe heel hits the floor – the point where most slips occur, in either WET or DRY conditions. Ramp indicates slip resistance in a slightly different manner, but an R rating is a recognised European method for measuring slip resistance.

Amtico Spacia 36+ in Weathered Oak with Extended R10 Slip Rating

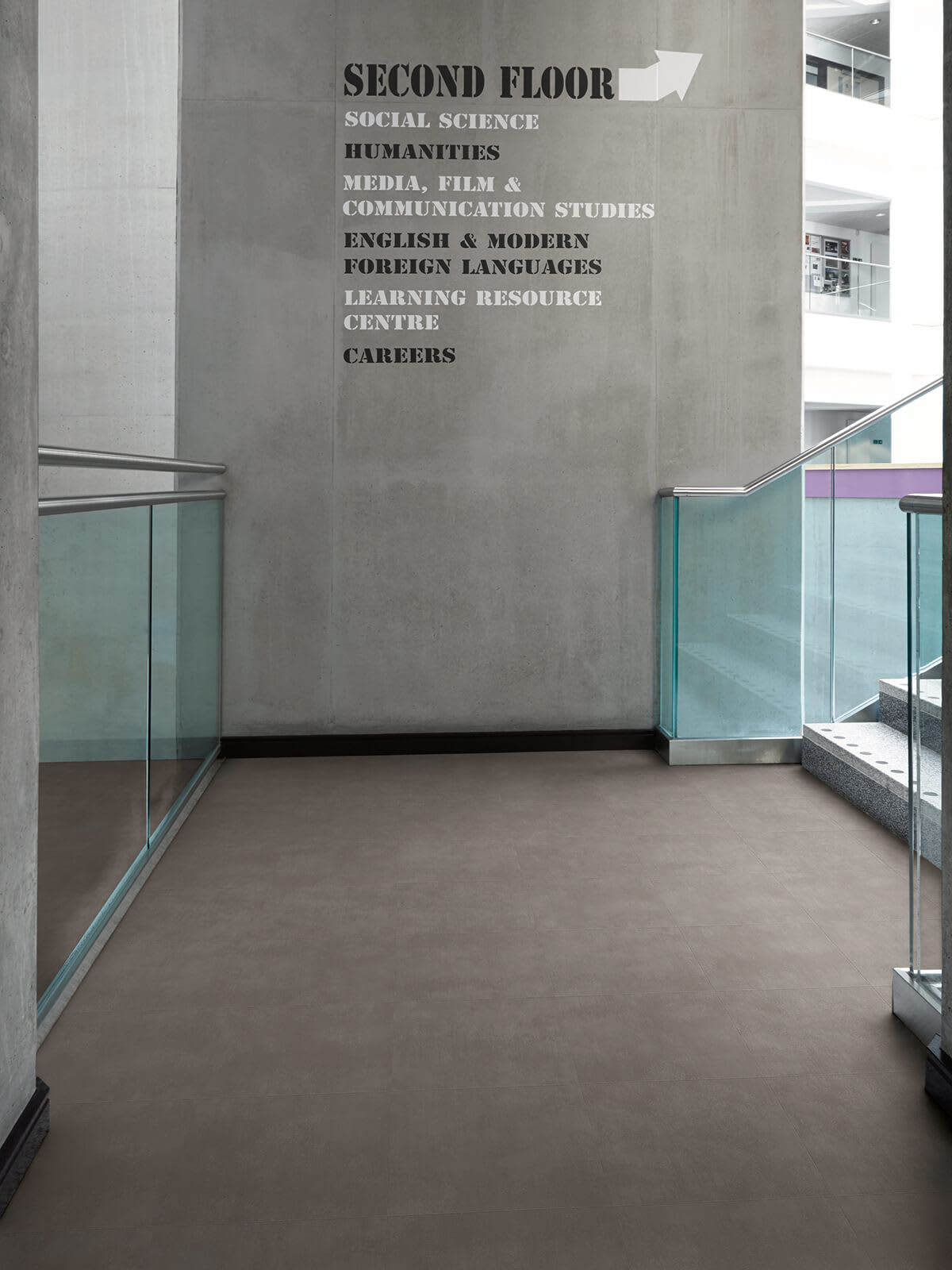

Amtico Spacia 36+ in Monument Concrete with Extended R10 Slip Rating

2. Surface Roughness

A safety floor should have a degree of roughness to its surface, either by means of an emboss – think steel tread-plate floors on stairs, or more commonly a micro-roughness that’s an indication of particulates added onto or within the flooring.

A note on particulates: A slip-resistant roughness treatment added to a surface may wear away, compromising the surface's slip potential. It’s better to look for a product with an integral, sustainable slip resistance – look for those with particulates added throughout the wear layer the floor tile or sheet. Some products will meet a 36+ in the WET or R10 as supplied by the manufacturer but these aren't safety floors as the resistance isn't sustainable - they won't have met the requirements of the enhanced slip standard.

3. Hygiene and Cleaning Regimes

All safety floors, whether safety sheet or LVT will be laid in spaces that need regular cleaning. Front-of-house spaces in bars and restaurants, retail or building entrances, will need to be safe and clean to function properly as well as a make the right impression.

We’ve created our Amtico Signature 36+ and Spacia 36+ collections for exactly this solution. A building benefits from safety flooring with enhanced slip resistance floors, as well as antimicrobial ingredients proven to resist the growth of potentially harmful bacteria between cleanings.

Enhancing hygiene protection should be an option for sensitive spaces like a school or care home where cross contamination of bacteria should be controlled. Antimicrobial technology added to a floor is an additional level of safety for the building's users, making a project more attractive to developer, healthcare managers or prospective employees of an office-based business.

We tested Signature 36+ and Spacia 36+ independently and achieved a 99.99% reduction in E.coli and MRSA after 24 hours.

4. Performance and Sustainability

The performance qualities of your choice of floor will be evident in a technical specification, from sustainability to slip resistance. We think safety floors should be judged by the same standards as you apply to other specified surfaces. Look for environmental certifications, recycled content and a manufacturer's commitment to sustainability. Amtico engages with third party assessors to ensure Amtico floors are certified independently, including BREEAM, LEED and WELL building systems. Most recently we’ve added the superior Indoor Air Quality Gold encompassing assessment criteria from 16 different sustainability accreditations. We’ve also achieved the latest ISO 14001:2015 standards for environmental systems management.

5. Air Quality Indicators

Healthy buildings can be assessed through the materials used within them and their effect on air quality. Look for materials with low VOCs or Volatile Organic Compounds. Excessive VOCs contribute to poor indoor air quality, so limiting our exposure to them will improve the building’s environmental rating. Look for products with Low VOCs, listed in Environmental Product Declarations, or EPDs on platforms such as:

Get in Touch

Choosing from the abundant options in safety flooring is ultimately an individual decision, but if you’re curious to see samples of Amtico Signature 36+ or Spacia 36+ get in touch regarding your project.